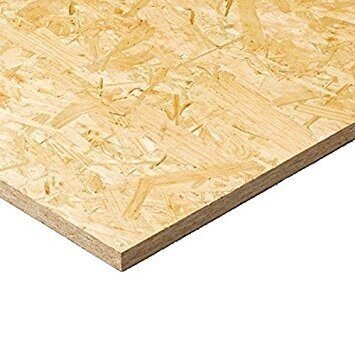

2440mm x 1220mm x 11mm OSB3 Board

2 440 x 1220mm x 11mm OSB3 Board

OSB (Oriented Strand Board), also known as sterling board, is formed by layering flakes of wood in a specific orientation. Its wooden strips are compressed and bonded together with wax and resin adhesive. OSB boards are versatile, strong and cost effective. They can also be used for structural and non-structural uses in dry conditions.

Key Features

- Ideal for sheds, boarding and hoarding, pallet tops, display boards, shelving, packaging, roofing, flooring and many other general applications

- No knots or voids

- Strong

- Versatile

Application

OSB is particularly appropriate for load-bearing applications in construction because of the structure of strands within its panels and its high mechanical properties. It is commonly used for roof decking, wall sheathing and flooring, but other functions are available where OSB is operated as a wood-based panel product. Large quantities of OSB are also used in site hoardings and pallet tops as well as industrial packaging and sarking. For ease of use it can be cut by a hand or power saw and machined (routed, spindled, planed and bored) with common woodworking machinery. When using powered tools it is recommended that Tungsten carbide cutting edges are used.

OSB 3 is designed for use where a high performance board is required which provides dimensional stability and load bearing capabilities especially suited for use in humid conditions.

Standard:

EN 300 - type OSB 3; EN 13501-1: Class D-s1, d0

Other Applications:

- Internal load - bearing cladding of walls and ceilings, partitions.

- Roofing, sarking and SIPS panels.

- Interior design.

- Billboard production

- Exhibitions (displays, Stands, Kiosks)

- Flooring base.

- Framework for upholstered furniture.

- Load-bearing wall sheathing.

- Packaging.

- Warehouse Management (Racks, fences, etc)